MGTES is Magaldi Green Energy’s proprietary thermal battery, designed to provide long-duration energy storage (LDES) and deliver medium- to high-temperature carbon-free heat for industrial decarbonization and grid flexibility.

This breakthrough Power-to-Heat (P2H) technology enables industries and power systems to transition from fossil fuels to carbon-free thermal energy, solving two of the biggest challenges facing clean energy adoption: the intermittency of renewables and dependency on volatile fuel prices.

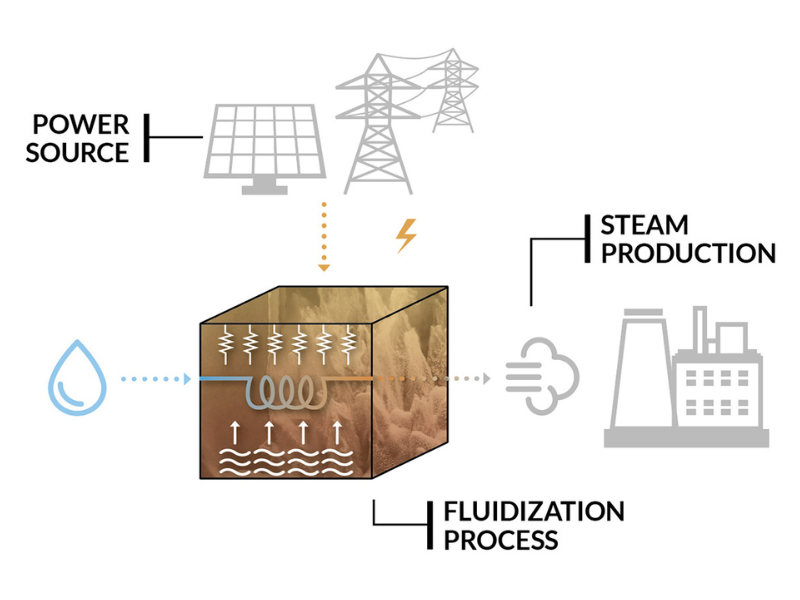

How it Works

At the heart of MGTES lies a simple yet robust principle: storing energy in a fluidized sand bed.

During the charging phase, surplus renewable electricity or low-cost grid power directly heats the fluidized bed of silica sand.

Once charged, the system switches to storage mode. The sand settles, locking in thermal energy with minimal losses, for hours, days, or even weeks.

When energy is needed, MGTES seamlessly discharges, transferring the stored heat from the fluidized bed directly to a working fluid - such as superheated steam - at temperatures up to 550 °C. This high-grade thermal energy can be supplied to industrial processes, ensuring on-demand dispatchability.

Inspired by Nature: Silica sand as storage medium

- High Thermal Stability

Even under repeated thermal cycling - Cost Efficiency

Extremely low cost and wide availability make it ideal for scalable solutions - High Heat Retention

With proper insulation, sand is effective for long-duration energy storage - Safety & Low Environmental Risk

Chemically inert and non-flammable - Lower Maintenance Requirements

No risk of freezing or clogging, which is a concern with molten salts at lower temperatures

Fluidization as key enabler

When using granular materials like silica sand in a TES system, fluidization offers several important technical benefits:

- Enhanced Heat Transfer

Fluidized bed allows direct contact between heat transfer surfaces and the particles, enhancing heat transfer and internal diffusivity, and enabling efficient energy input/output - Uniform Temperature Distribution

Heat is more uniformly distributed throughout the storage medium, reducing thermal gradients. - Rapid Thermal Response

Due to increased surface area and contact efficiency, fluidized system can charge and discharge heat quickly, improving responsiveness

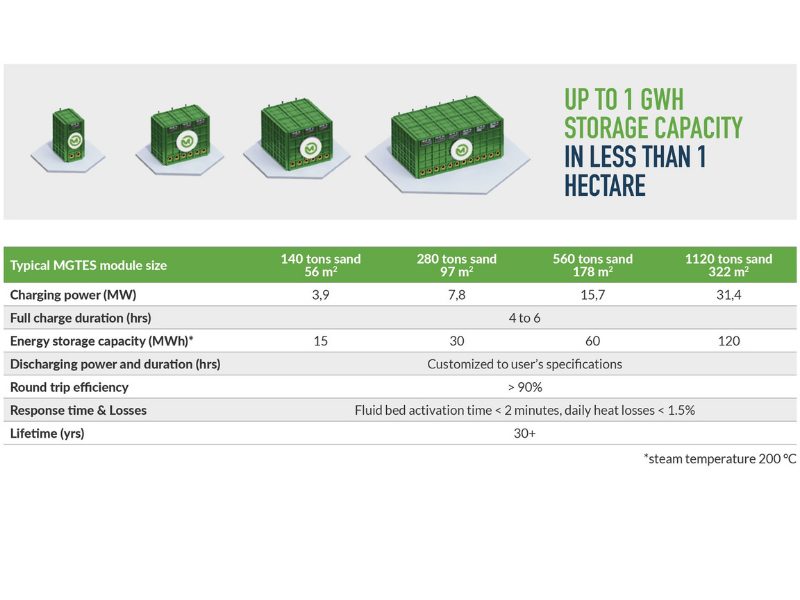

Modularity

MGTES is designed as a modular system, enabling flexible deployment tailored to specific thermal energy demands. By selecting the mass of solid particles contained in each module, the thermal storage capacity of a single module can be configured over a wide range from 5 MWh to +100 MWh.

MGTES’s modular approach offers a future-proof thermal storage solution that grows with your decarbonization goals.

- Scalable Design

Easily increase storage capacity by adding new modules as energy needs grow or production lines expand. - Custom Integration

Adapt system configuration to different industries, space constraints, or temperature requirements. - Staged Investment

Start small, then scale over time - minimizing upfront capital investment while maximizing long-term value. - Operational Redundancy

Modular units can operate independently, ensuring system resilience and reducing downtime during maintenance. - Fast Deployment

Standardized modules simplify engineering, manufacturing, and installation, accelerating time-to-operation.

Dive deeper into MGTES

A New Standard for Industrial Heat

Industrial heat is the backbone of modern production, yet it is also one of the hardest sectors to decarbonize. Today, most energy-intensive processes - from chemicals and food to textiles and mining - rely on fossil fuels to deliver the high temperatures they require.

MGTES changes that equation.

By providing carbon-free heat on demand, MGTES allows industries to replace gas boilers or integrate CHP plants with a clean, reliable alternative. This shift brings multiple advantages.

Because MGTES can be charged when electricity prices are low and discharged whenever required, it lowers the average cost of industrial heat while reducing exposure to volatile gas markets. It also improves energy security, cutting dependence on imported fuels.

Thanks to its modular design, the system can be scaled to fit both small and large industrial sites, delivering the flexibility that production lines demand.