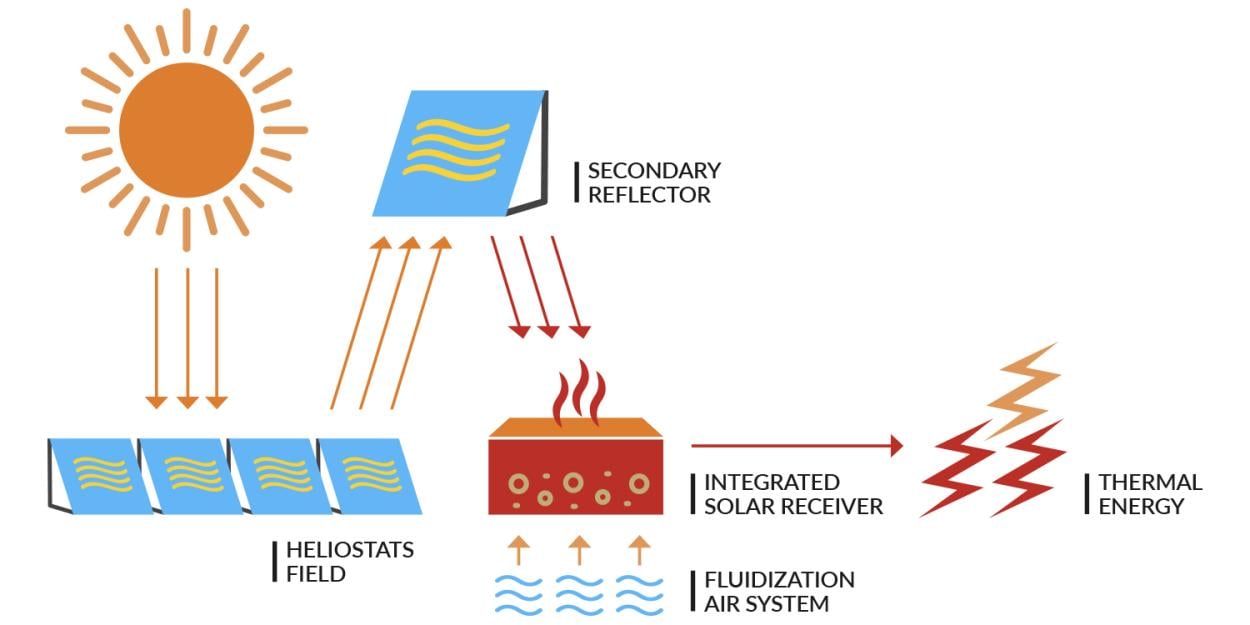

STEM® (Solar Thermo-Electric Magaldi) is a patented Concentrated Solar Thermal technology with integrated Thermal Energy Storage (TES), designed to deliver clean energy whenever and wherever it’s needed.

How does it work?

The system captures solar radiation through a field of heliostats that reflect sunlight toward a secondary reflector (“beam-down” configuration), focusing it onto a fluidized sand receiver.

Silica sand serves as both a heat transfer medium and a storage material. Fluidized air enables the sand to reach temperatures of ~600–1,000 °C uniformly and reliably, storing solar energy that can be released either as high-temperature heat or converted into steam for power generation.

Features & Benefits

Dispatchability

STEM® ensures a continuous energy supply, even at night or during cloudy periods.

Unlike molten salt CSP systems, whose storage capacity is limited to the size of hot and cold tanks (typically 6–15 hours of dispatchability), STEM® stores energy directly in sand, with no practical limit on storage duration and without the standby energy costs associated with freeze protection. Also, thanks to advanced insulation, heat losses over time remain minimal.

Sustainability

Molten salt systems rely on corrosive nitrate mixtures that solidify at ~240 °C, necessitating continuous heating and the use of costly alloys to prevent freezing and degradation.

STEM®, on the other hand, uses abundant, low-cost, and recyclable materials such as silica sand, glass, and steel. In particular, sand is non-toxic, cheap, and completely stable at ambient conditions: it neither corrodes equipment nor requires freeze protection. This makes STEM® mechanically more robust and easier to operate over its lifetime.

Scalability

STEM® is scalable and can be configured for small- to mid-scale applications (5–20 MWe).

Its compact footprint reduces land-use requirements and simplifies site selection and permitting. Unlike traditional CSP plants, which are typically located in remote desert areas, STEM® can be deployed closer to industrial sites or even near urban centers - cutting transmission needs and enabling direct integration into industrial processes.

Applications

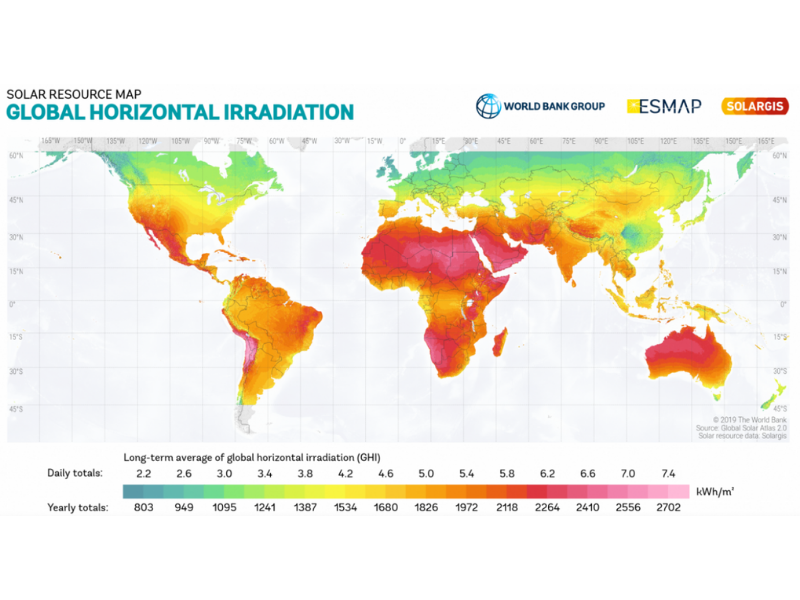

In regions with high to very high Direct Normal Irradiance (DNI, 2,000–2,500 kWh/m²/y), STEM® is ideally suited to support the energy transition and accelerate industrial decarbonization.